Self Reclosing Explosion Doors

The TV Explosion Door from ATEX is a high performance explosion venting solution for aggressive environments. It provides economical explosion relief and prevents secondary fire damage from oxygen intake by rapidly self re-closing after the explosion is vented. The cement and steel industries have a long association with coal as a source of heat in their kiln plant but now they experience the changing times of more sustainable fuels sources from tyres to sludge pellets.

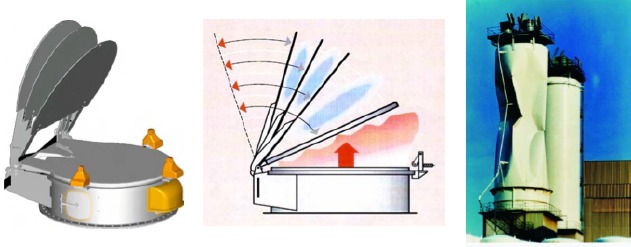

THE SELF RECLOSING DOOR METHOD

Since most of the plant is located outside, venting is not a major problem but you need to vent a lot of kinetic energy from the mills, filter or silos preventing the reintroduction of flesh air after the explosion event to minimise subsequent fires or secondary explosions.

The most popular choice for endurance and efficiency is the TV self reclosing vent doors and flame diverters.

In the example below, Vent 1 vents the primary explosion force reducing the velocity to the filter. Vent 2 diverts the resultant slower flame from the filter. The filter and silo are then vented as individual components without the concern of pressure piling or flame jet ignition.

FEATURES

Many of these systems are further protected by inerting using Nitrogen or CO2. This is only possible with a self reclosing door. Important in these industries are the durability of the explosion door and its self reclosing feature to prevent the ingress of air after the explosion, minimising the potential fire damage.

AVAILABLE OPTIONS

- Construction: hot-dip-galvanised steel or stainless steel.

- Vacuum breakers

- Heating system (prevents obstruction by freezing weather)

- Proximity switch to initiate emergency shutdown & can be used to actuate secondary protection devices.

EXPLOSION DOOR CONCEPT AND OPERATION

Self-reclosing Explosion Doors open against one or more baffle plates to absorb its kinetic energy. This dramatically reduces damage to the supporting structure. After venting the door re-closes and the unique door catches reseal the vent opening, minimizing the damage from fire. In contrast, standard Explosion Vent Panels allow air supply into the protected vessel after the initial explosion, increasing the potential damage from fire, especially in dust collectors and silos.

The explosion doors can be round or rectangular, to facilitate most industrial applications. The round explosion doors are ideal for silos and other vessels requiring top-mounting. The rectangular explosion doors are available for heavy and light industrial environments. The units can be mounted in a horizontal or vertical position. The heavy industrial explosion doors are used on vessels such as dust collectors. The light industrial units can be used on weak structures such as buildings. After explosions in virtually closed vessels, rapid cooling can cause destructive vacuums. An integrated vacuum breaker is available to prevent implosion.

Air Cushioned RLE door ideal for dust filters. Easy to install these doors can be angled to deflect the flame upwards to a safe vent area while transmitting the forces into the filter structure.

A fire like this one, which is supported by the O2 in the air ingress via the non-re-closing explosion vents, can be avoided or mitigated by using self-re-closing explosion vents!

- Fast response time

- High efficiency vent area

- Designed for aggressive environments

- Long service life (low maintenance)

- Low cost of operation

- Spring-assisted automatic re-close prevents oxygen ingress and the ‘chimney’ effect.

- Air-cushion design causes smooth deceleration, avoiding damage to the supporting structure.

- Optional vacuum breakers protect against implosion caused by rapid air cooling inside the vessel.